Introduction

In today’s world, access to clean and safe drinking water is a paramount concern. With increasing pollution and water scarcity, water purification has become a necessity. Reverse Osmosis (RO) plants have emerged as a highly effective solution to address these challenges. Among these, the 1000 LPH RO plant stands out as a powerful tool for medium to large-scale water purification needs. This comprehensive guide will delve into the intricacies of RO plants, from their working principles to their benefits and maintenance tips.

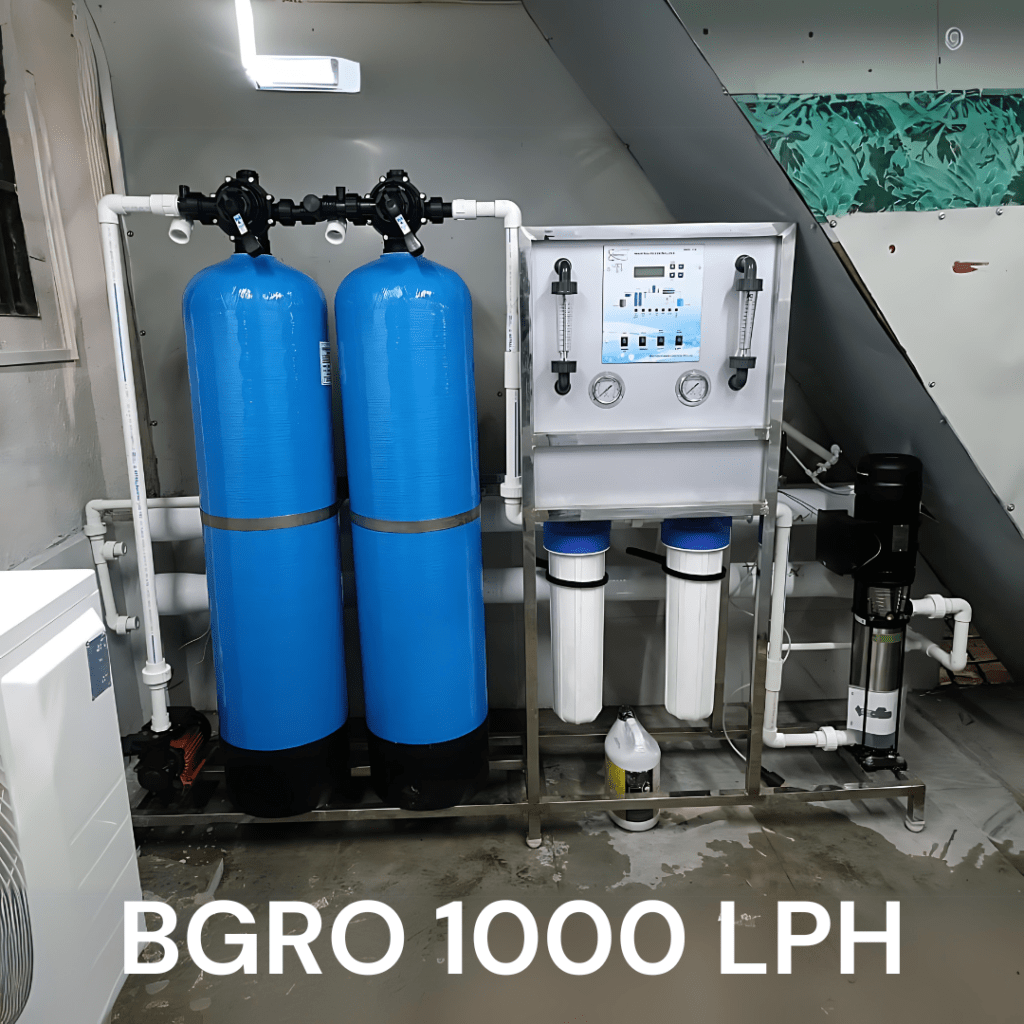

Understanding the 1000 LPH RO Plant

A RO plant is a water purification system capable of producing up to 1000 liters of purified water per hour. This makes it an ideal choice for various applications, including:

- Commercial Establishments: Hotels, restaurants, and shopping malls

- Industrial Facilities: Manufacturing plants, pharmaceutical industries

- Healthcare Institutions: Hospitals, clinics, and laboratories

- Educational Institutions: Schools, colleges, and universities

How Does a 1000 LPH Reverse Osmosis (RO) Plant Work?

The RO process involves several stages to ensure the highest quality of purified water:

- Pre-filtration: Water is initially passed through coarse filters to remove large particles like sand, dirt, and rust.

- Carbon Filtration: Activated carbon filters remove chlorine, organic matter, and unpleasant odors, improving the taste and smell of water.

- Reverse Osmosis: The heart of the RO process, this stage involves forcing water through a semi-permeable membrane. This membrane allows water molecules to pass through while rejecting impurities like dissolved salts, heavy metals, bacteria, and viruses.

- Post-filtration: The purified water is further treated with a fine filter to remove any remaining particles and ensure a crystal-clear product.

Key Features of a 1000 LPH Reverse Osmosis (RO) Plant

- High Capacity: Efficiently produces 1000 liters of pure water per hour.

- Multi-stage Filtration: Combines multiple filtration techniques for comprehensive purification.

- Automated Control: Advanced automation systems for ease of operation and monitoring.

- Energy Efficiency: Designed to minimize energy consumption, reducing operational costs.

- Durable Components: Constructed with high-quality materials for long-lasting performance.

- High-quality Membranes: Utilizes advanced RO membranes for superior filtration.

Benefits of Using a 1000 LPH Reverse Osmosis (RO) Plant

- Pure and Safe Drinking Water: Removes harmful contaminants, ensuring safe consumption.

- High Water Output: Meets the demands of large-scale operations.

- Cost-Effective: Long-term savings on bottled water and maintenance costs.

- Environmentally Friendly: Reduces plastic waste and conserves water resources.

- Improved Water Taste and Odor: Delivers refreshing, great-tasting water.

Applications of 1000 LPH Reverse Osmosis (RO) Plants

- Commercial Establishments: Provides clean water for drinking, cooking, and cleaning.

- Industrial Facilities: Supplies pure water for various industrial processes, such as boiler feed water and chemical processing.

- Healthcare Institutions: Ensures sterile water for medical procedures and patient care.

- Educational Institutions: Provides clean drinking water for students and staff.

Installation and Maintenance

Installation Process

- Site Selection: Choose a suitable location with adequate space and access to water and power supplies.

- Plumbing and Electrical Work: Install necessary plumbing and electrical connections.

- Assembly: Assemble the pre-filters, carbon filters, RO membrane, and post-filters.

- Testing and Calibration: Test the system for leaks and calibrate it for optimal performance.

- Final Inspection: Ensure that all components are functioning correctly and the system is ready for operation.

Maintenance Tips

- Regular Filter Replacement: Replace filters as recommended by the manufacturer.

- Membrane Cleaning: Periodically clean the RO membrane to maintain its efficiency.

- Water Quality Monitoring: Regularly monitor the quality of the purified water.

- Sanitization: Sanitize the system to prevent bacterial growth.

- Leak Detection: Check for leaks and repair them promptly.

Choosing the Right 1000 LPH RO Plant

When selecting a 1000 LPH RO Water plant, consider the following factors:

- Water Quality: Assess the quality of your source water to determine the appropriate filtration system.

- Brand Reputation: Choose a reputable brand with a proven track record.

- After-Sales Service: Opt for a supplier that offers reliable after-sales support.

- Energy Efficiency: Consider energy-efficient models to reduce operating costs.

- Capacity: Ensure the plant’s capacity meets your specific water requirements.

Frequently Asked Questions (FAQs)

- How long does a 1000 LPH RO plant last?

With proper maintenance, a well-designed RO plant can last for several years. - What is the operating cost of a 1000 LPH Reverse Osmosis (RO) plant?

Operating costs primarily involve electricity consumption, filter replacements, and maintenance. - Can a 1000 LPH RO Water Treatment plant be used for residential purposes?

While primarily designed for commercial and industrial applications, it can be used in large residential complexes or for high-demand households. - What is the difference between a 1000 LPH RO Water Treatment plant and a smaller capacity plant?

A 1000 LPH plant can handle higher water demands, making it suitable for large-scale operations.

Conclusion

A 1000 LPH RO plant is a valuable asset for any organization seeking a reliable and efficient solution for water purification. By understanding its working principles, benefits, and maintenance requirements, you can make an informed decision and ensure the long-term success of your water purification system. Invest in a high-quality RO plant to safeguard your health, protect the environment, and meet your water needs.